TOKYO — (BUSINESS WIRE) — April 18, 2017 — Toshiba Corporation's (TOKYO:6502) Storage & Electronic Devices Solutions Company today announced the launch of “TB67S289FTG,” a stepping motor driver with a Toshiba developed architecture that automatically detects and prevents stalling during operation. Mass production is scheduled to begin in the end of July 2017.

This Smart News Release features multimedia. View the full release here: http://www.businesswire.com/news/home/20170418006703/en/

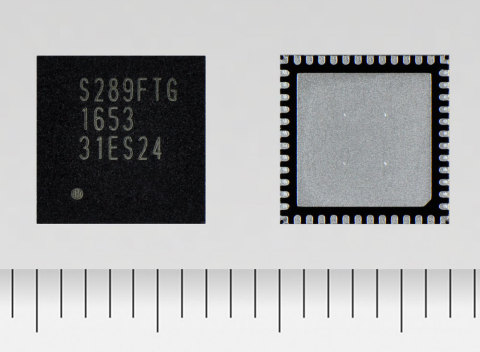

Toshiba: "TB67S289FTG," a stepping motor driver with a Toshiba developed architecture that automatically detects and prevents stalling during operation. (Photo: Business Wire)

Stable and highly precise control is a basic operating requirement, for motors used in printers, office appliances, banking terminals such as ATMs, cash dispensers, amusement machines, and home appliances. Recent demand has also emphasized more efficient motor drivers that use less power and generate less heat generation.

Avoiding stalls in stepping motor operation is the highest priority for

securing stability and precision in motor control, and is achieved by

provision of additional current to assure an operating margin for the

motor. Real-time monitoring of motor torque and current feedback, using

additional sensors and highly advanced MCU control, are also required to

improve efficiency and heat generation.

A further way to improve

efficiency and cut down heat generation is to adjust the built-in

MOSFET's on-resistance and cut down power loss during operation.

The TB67S289FTG is the first stepping motor driver to apply Toshiba’s original anti-stall and efficiency improvement system, Active Gain Control (AGC)[1], which enables the driver to monitor the motor and torque, and automatically optimizes motor control without additional MCU control. In operation, TB67S289FTG prevents motor stalls and automatically optimizes motor current, depending on torque needed. Compared with current solutions, TB67S289FTG cuts down the motor power by up to 80% at best, winning significant improvements in efficiency and heat improvement without relying on on-resistance.

Further efficiencies can also be achieved when the new stepping motor driver is supported by ACDS[2], Toshiba’s sense-resistor-free current monitor and control system, which allows more free space and uses fewer external components on the PCB.

Toshiba positions the TB67S289FTG as its flag-ship stepping motor driver, a high performance motor control and component reduction solution, and will continue to expand its line-up.

Main Features

1. Anti-stall and high efficiency

Toshiba’s new motor control

architecture AGC for anti-stall and high efficiency motor control. Plus

sense-resistor-less current control ACDS for additional PCB space.

High-resolution 1/32 step (max.) motor control cuts down noise and

vibration.

2. Lower heat generation

Heat generation is reduced by low

on-resistance (0.46 Ω (upper + lower: typ.)).

3. Small package

Packaging in a small QFN package allows customers

to reduce heat problems and simplify PCB design patterns for heat

dissipation. It will also realize affordable solutions in terms of space

and cost.

4. Built-in error detection circuits

Thermal shutdown, over-current

shutdown, under voltage lock-out and motor load open detection circuits

contribute to equipment safety and reliability. Also, error status can

be flagged to MCU using error flag function.

|

Main Specifications of New Product |

||

| Product name |

TB67S289FTG |

|

| Control I/F |

CLK-IN |

|

| Absolute maximum ratings | 50V, 3A | |

| Package | QFN48 | |

| Step resolution | Full, Half, Quarter, 1/8, 1/16, and 1/32 step resolution | |

| Other features |

- AGC; a current control method for anti-stall and high efficient

motor operation

|

|

| Mass production | End of July, 2017 (scheduled) | |