Company's future AM approach is to manufacture right first time

HAMBURG, Germany — (BUSINESS WIRE) — January 31, 2019 — BAE Systems Air, a multinational defense, security, and aerospace company, has chosen MSC´s Simufact Additive software for the simulation of metal AM components after a long assessment of all the major AM simulation tools. BAE Systems opened back in 2015 a new Product and Process Development Centre, where they have conducted trials of the market leading packages for the simulation of metal AM processes. At the end of this trial phase, they have concluded that Simufact Additive software can deliver good results and they gained great confidence from the trials that they have carried out. Furthermore, BAE Systems is already using other MSC Software products such as MSC Nastran, Patran, and MSC Apex. Hence, products are coming from one single source, which is a big bonus to them if they keep the process simulation chain in mind.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20190131005454/en/

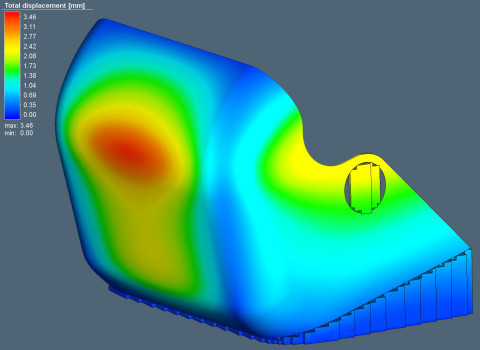

Distortion of a simulated NVG (night vision goggles)– Source BAE Systems (Copyright BAE Systems plc.)

“For MSC Software, BAE Systems Air is a great partner because it shows that we offer best-in-class solutions and with our MSC One product token system a complete portfolio of solutions can easily be deployed that works hand in hand with BAE’s applications,” Paolo Guglielmini, CEO MSC Software added.

Reduce the number of build trials from more than five to two

Aircraft

manufacture is undergoing a move towards higher variety, more

specification requirements and lower batch volumes, rather than orders

being placed for hundreds of aircraft at a time. Aircraft manufacturers

have to consider orders with a batch size of ten or twenty. Of course,

this change drives the need to manufacture components for aircraft

differently, and explains that additive manufacturing will be a key

technology enabler to meet customer demands. While manufacturing

components additively, BAE systems must face the main challenges of

residual stresses and distortions. Before they employed a simulation

software, in some cases they had to complete five or six build trials,

which are costly and time-consuming. Now they can reduce it to just two

builds per component with the future opportunity, through

experience, reducing to a ‘right first time’ approach. At this stage,

they are pleased that their Application Engineers will use the MSC

software solution that enables them to create the build preparation of a

component in order to get the best orientation and support strategies

for a particular build. Employing Simufact Additive, BAE Systems is now

able to reduce the distortion in components by more than 70 per cent at

the first iteration step.

“We are proud that one of the largest defense contractors in Europe, and a company that is among the world’s largest defense entities, decided on Simufact Additive to roll out their additive manufacturing processes. The trust BAE have put in us reinforces our approach and the great work being done by our development team,” says Dr. Hendrik Schafstall, Simufact´s CEO and Managing Director.

For download of press pictures please go to the Simufact website.

More features can be found on the Simufact website.

About Simufact

Simufact Engineering – an MSC Software

company – is a global operating software company providing process

simulation solutions and services to manufacturing industries. More than

20 years’ experience with providing simulation solutions for the design

and optimization of manufacturing techniques in metal processing and a

dynamically growing customer base exceeding a number of 1,000 customers

have made the Hamburg (Germany) based supplier a leader in this business

area. The software primarily aims at the automotive industry, mechanical

engineering, aerospace industry and their respective suppliers. Typical

fields of application for Simufact software are hot forging, cold

forming, sheet metal forming, rolling, ring rolling, open die forging,

mechanical joining, heat treatment, different welding processes, and

additive manufacturing. Learn more at

simufact.com

and follow us

@Simufact.

About MSC Software

MSC Software is one of the ten original

software companies and a global leader in helping product manufacturers

to advance their engineering methods with simulation software and

services. As a trusted partner, MSC Software helps companies improve

quality, save time, and reduce costs associated with design and test of

manufactured products. Academic institutions, researchers, and students

employ MSC’s technology to expand individual knowledge as well as expand

the horizon of simulation. MSC Software employs 1,400 professionals in

20 countries. MSC Software was acquired by

Hexagon

AB (Nasdaq Stockholm: HEXA B) in 2017. For additional information

about MSC Software’s products and services, please visit:

www.mscsoftware.com

Simufact, Simufact Forming, Simufact Welding, and Simufact Additive are trademarks or registered trademarks of Simufact Engineering GmbH. All other trademarks belong to their respective owners.

View source version on businesswire.com: https://www.businesswire.com/news/home/20190131005454/en/

Contact:

Volker Mensing

Director Marketing & Communications

simufact

engineering gmbh

+49 (0)40 790 128-160

Email Contact

Penelope Friebel

Public Relations & Social Media

simufact

engineering gmbh

+49 (0)40 790 128-164

Email Contact