LONGMONT, Colo., May 07, 2019 (GLOBE NEWSWIRE) -- 3D at Depth Inc., the world's leading expert in subsea laser LiDAR technology and 3D data solutions, recently announced the expansion of their non-touch vibration and leak detection solution designed to help customers increase the reliability, integrity, and safety of their underwater assets and structures. As the complexities of offshore oil and gas production continue to increase, and the pressure to reduce risk, lower capital costs, and decrease downtime are required, these factors present a clear opportunity for 3D at Depth's Subsea laser LiDAR (SL3) technology and 3D data solutions. The SL3 technology has been used successfully across multiple vibration projects around the world in water depths up to 2300 meters. Many of the vibration measurements occurred at the same time during drilling and production operations. Valuable 3D information such as drill cutting assessments and volume surveys were acquired in real time. In addition, several comprehensive projects included: the slow transient movement of a wellhead while connected to the blowout preventer and drilling risers at around 0.14 Hz as well as during work over intervention operations. The controllable beam allowed multi-location measurements which can later monitor vibration and also offer analysis with mode effect translations.

|

|||||

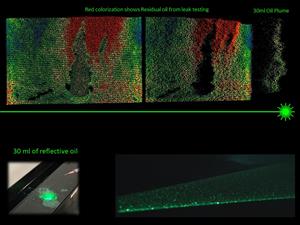

The core technology also locates reflective fluids with a higher reflectivity than seawater to identify and locate leaks from production or commissioning fluids such as Mono-ethylene glycol (MEG); hydraulic production control fluids, and oils. After witnessing real-world examples of leaks in open water projects, 3D at Depth recently conducted baseline tests in a tank to show the capability of the SL3 laser LiDAR as a leak detection solution. The test added 30 milliliters of BP Castrol Transaqua HT oil into a tank and confirmed that with non-tracer additives in the oil, the SL3 laser solution could detect leaks from distances of 12 meters away. Furthermore, when a "light-colored" tracer was used, the SL3 demonstrated the potential to identify leaks up to the full operational range of 45 meters. Testing thus proved the SL3 laser LiDAR is a viable solution in leak detection.

“SL3 technology and our powerful backend algorithms continue to provide critical information to help operators make more informed decisions,” stated Neil Manning, Chief Operating Officer of 3D at Depth Inc. “Structural and piping vibration can lead to severe consequences that can affect worker safety, environmental protection and corporate liability. Our ability to provide customers with a reliable 3D measurement for vibration identification and leaks while being deployed from a rapid non-touch tool is unique. In addition, added integrity value can be shown on the backend of dynamic well center and pipeline inspection campaigns. Customers can consistently experience additional value beyond the scope of each project as we continue to provide them with the right kind of business intelligence to achieve long term results and minimal maintenance shutdown periods.”

About 3D at Depth:

3D at Depth, Inc. provides advanced subsea LiDAR (SL) laser systems, survey support services, and 3D point cloud collection, visualization, and analysis solutions to help clients optimize marine, underwater and offshore survey campaigns. The precise, repeatable, millimetric 3D point clouds acquired through patented SL laser technology provides greater insight to measure, map and evaluate underwater assets, resources, and environments. From data collection and processing, through visualization and analysis, clients can "measure in 3D and manage in 4D" to increase operational efficiencies and reduce downtime. The Company's locations in Australia, Europe, and the United States support customer survey operations around the world. For more information and a broader listing of services visit us at

www.3datdepth.com and

LinkedIn, or follow us on twitter @3DatDepth.

Media Contact:

3D at Depth:

Colleen Hahn

+1.703.851.6944

media@3datdepth.com

A photo accompanying this announcement is available at http://www.globenewswire.com/NewsRoom/AttachmentNg/11caeb6f-7da8-49ce-9dbd-cebd80cbe979