GALESBURG, Mich. — (BUSINESS WIRE) — July 6, 2020 — Power management company Eaton today announced its Vehicle Group has been leveraging advanced Industry 4.0 technology to help its global operations safely navigate the ongoing COVID-19 crisis and continue to service its customers.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20200706005096/en/

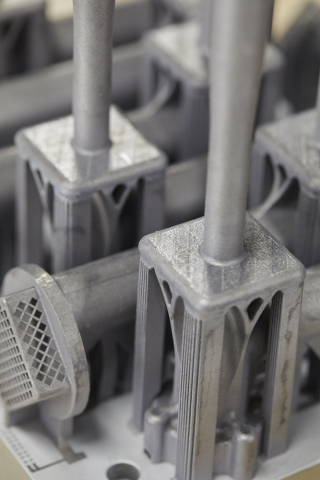

3D-printed latticed aluminum aerospace parts, which were produced with Laser Powder Bed Fusion on a Concept Laser M2 UP1 3D printer. (Photo: Business Wire)

Eaton’s Vehicle Group envisions Industry 4.0 as both operational and informational technologies, enabling autonomous production systems that are connected, optimized, transparent, proactive, and agile. Supported by an integrated ecosystem, the technologies are composed of augmented reality, rapid application development, autonomous robots, digital simulation, and additive manufacturing.

“I’m proud of our Vehicle Group team and their ingenuity, especially during the COVID-19 pandemic,” said João Faria, president, Vehicle Group. “By leveraging augmented reality, we are able to continue to support our operations remotely and continue the development of new products, ensuring our customer deadlines are met despite the global challenges we are all facing.”

Here are examples of how the Vehicle Group is using Industry 4.0 technologies:

Displaying 3D images and connecting remotely to improve safety

To enable remote assistance and critical activities, Vehicle Group teams are using Microsoft’s HoloLens 2 augmented reality goggles that offer the capability to display 3D images in physical spaces and connect remotely. This remote assistance technology ensures that ongoing work can be performed while keeping everyone safe.

Enhancing training and expediting review processes through augmented reality

Augmented reality also assists with knowledge retention and ongoing training. For instance, the Vehicle Group identified an opportunity to use the technology to train operators and engineers on new equipment, which would have traditionally been conducted by instructors who travel to the various remote sites. Additionally, the technology has proven critical for recent customer reviews and approvals.

Analyzing data to reduce costs, improve quality and reduce lead times

Eaton’s Vehicle Group is interconnecting plant systems and machines to collect, analyze and report real-time information, which optimizes plant floor management and provides visibility to real-time production issues in order to address them right away. These efforts are designed to reduce lead times; maintenance, repair and operations (MRO), inventory, indirect-labor/direct-labor costs; as well as increase performance and improve quality.

Implementing robots to promote safe distancing and increase productivity

To optimize manufacturing flow and eliminate the need for forklifts and other human-operated transport machinery, the Vehicle Group is using autonomous automated guided vehicles (AGVs) or autonomous mobile robots (AMRs). In addition to improving the flow of materials throughout a manufacturing facility, AMRs and autonomous AGVs increase safety and allow for social distancing while also lowering costs.

COBOTs, which are robots intended to interact with humans in a shared space or to work safely in close proximity, are being used to safely handle complex and repetitive tasks. This results in improved consistency and accuracy during the manufacturing process.

Using digital simulation to improve production efficiency

Another way the Vehicle Group is increasing productivity is by using digital simulation applications to define which solution and/or combination of factors will result in the highest output. These applications can run several scenarios by changing parameters, such as the number of operators, work in process material, cycle times, operator standardized work and many others. The applications are being used to define new manufacturing cells and assembly lines or to redesign existing ones. In most cases, the Vehicle Group is seeing productivity increase from 10 to 30 percent via higher production output or reduced amount of investment needed.

Leveraging 3D printing tools internally to expedite processes

Additive manufacturing is leveraged to improve safety, quality and efficiency by designing and producing tools, poke-yokes and gauges internally on both polymer and metal materials. This allows fast reactions (shorter lead times), reduced purchase costs and highly customized solutions. For example, lead times can be reduced from weeks to days, while reducing costs from thousands to hundreds.

Eaton’s mission is to improve the quality of life and the environment through the use of power management technologies and services. We provide sustainable solutions that help our customers effectively manage electrical, hydraulic, and mechanical power – more safely, more efficiently, and more reliably. Eaton’s 2019 revenues were $21.4 billion, and we sell products to customers in more than 175 countries. We have approximately 95,000 employees. For more information, visit www.eaton.com.

View source version on businesswire.com: https://www.businesswire.com/news/home/20200706005096/en/

Contact:

Thomas Nellenbach

thomasjnellenbach@eaton.com

(248) 226-6852 (office)

(216) 333-2876 (cell)