SOUTHFIELD, Mich. — (BUSINESS WIRE) — October 21, 2020 — Power management company Eaton today announced its Vehicle Group is implementing a new 3D metal printing program as a part of its Industry 4.0 strategy to reduce development time and improve efficiency. The first metal printer system was installed at the Kings Mountain, N.C., facility, and a global deployment of 3D polymer printing technology is slated to be completed by first-quarter 2021.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20201021005571/en/

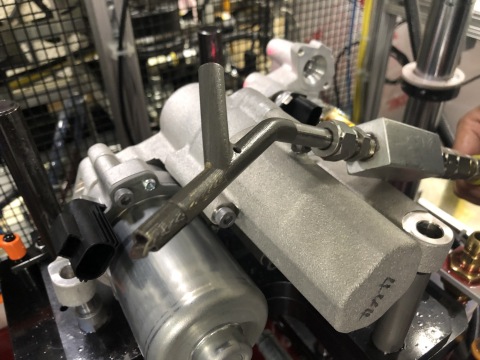

Eaton’s Vehicle Group reduced cost and development time using its 3D metal printing capabilities to produce this oil fill nozzle. (Photo: Business Wire)

The 3D printers are being utilized to create high-quality fixtures, safety devices, automation grippers for assembly and handling, and maintenance components requiring replacement. Prototype development is following the same strategy to support faster product development trials and improve efficiency.

Improving output and efficiency

To speed up the design process, scanners are used to create 3D models of existing components. This process allows components to be reverse-engineered to better leverage 3D printing capabilities, including changing component design to use less material, the addition of different topography elements or consolidating multiple components into a single part.

As an increasing number of 3D printers are deployed across the globe, Eaton’s Vehicle Group has been realizing further operational improvements including lead-time reduction and cost savings.

The 3D printing technology adds material only where it is needed and allows more advanced designs to be developed. Together, these two factors reduce the amount of post-processing operations needed while reducing material cost.

A closer look at 3D printing

The process to print metal parts and components begins with powdered metal stored in a rod and held together by wax and a polymer binder. Similar to extrusion, the metal is melted, and the 3D printer begins to add layer after layer, based on its programmed schematics.

Once the printing process is complete, the part or component is run through a chemical bath to remove most of the polymer binder. The part then goes through a furnace to remove the remaining wax and polymer, and to fuse the metal material in a high-density structure. Depending on what the printed part or component is to be used for and which material it was printed with, an additional heat treatment process can be performed to increase part strength even further.

The total lead time to get a component printed depends on several criteria, including the size and intricacy of the part. Depending on the part or component design and required tolerances, it also can undergo post-processing. The debinding operation and heat treatment are done in batches, with several different components going through these processes together while the next components are being printed. Although the printer, debinding and furnace work in an integrated loop, there is flexibility to increase the number of printers without having to duplicate either the debinding or furnace.

Going forward, the Vehicle Group’s 3D printing capabilities will be used to further reduce production time and drive efficiency. Learn more about the Vehicle Group’s Industry 4.0 technologies and benefits.

Eaton’s mission is to improve the quality of life and the environment through the use of power management technologies and services. We provide sustainable solutions that help our customers effectively manage electrical, hydraulic, and mechanical power – more safely, more efficiently, and more reliably. Eaton’s 2019 revenues were $21.4 billion, and we sell products to customers in more than 175 countries. We have approximately 92,000 employees. For more information, visit www.eaton.com.

View source version on businesswire.com: https://www.businesswire.com/news/home/20201021005571/en/

Contact:

Thomas Nellenbach

thomasjnellenbach@eaton.com

(216) 333-2876 (cell)