- New tool provides per-part estimate for binder jetting on any metal ExOne Pro series 3D printer

- It’s now easy to compare binder jetting to other traditional and additive manufacturing methods

- ExOne is confident its industrial systems offer the best value in terms of build area, throughput, consumable costs, material flexibility and more

NORTH HUNTINGDON, Pa. — (BUSINESS WIRE) — January 12, 2021 — The ExOne Company (Nasdaq: XONE), the global leader in industrial sand and metal 3D printers using high-speed binder jetting technology, has launched a new online estimating tool for companies considering moving production of metal parts to high-speed binder jet 3D printing.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20210112005220/en/

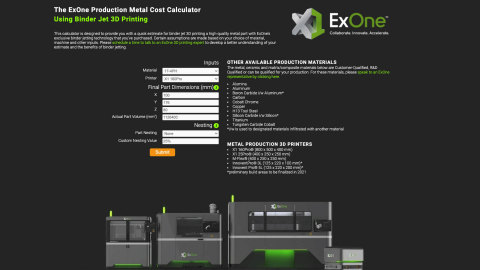

The new ExOne Production Metal Cost Calculator provides manufacturers with a per-part estimate for binder jet 3D printing a precision metal part, so the technology can easily be compared to other traditional and additive manufacturing technologies. The tool is available at exone.com/productioncalculator. (Photo: Business Wire)

The ExOne Production Metal Cost Calculator is designed to provide manufacturers with a per-part estimate for binder jet 3D printing a precision metal part so they can quickly compare the technology to other forms of traditional and additive manufacturing.

The new tool requires just a few easy inputs – material, machine, part dimensions and volume – and is based on the purchase of any one of ExOne’s four Pro series printers, a lineup that competes with existing systems from Digital Metal and new binder jet systems from Desktop Metal, GE and HP.

“As customers compare new binder jetting options in the marketplace, we wanted to provide greater transparency into the affordable costs of binder jetting with ExOne technology,” said John Hartner, ExOne’s CEO. “Our new estimating tool takes a comprehensive range of costs into account, such as initial capital investment, throughput speeds, material, binder, replacement printheads, and more. Our team is confident that our high-speed systems offer the best value in terms of build area, throughput, consumable costs, material flexibility, and experience.”

ExOne’s production-ready lineup includes the:

- X1 25Pro® large metal 3D printer, which launched in 2019 and is being successfully used by many manufacturers worldwide today. It offers a maximum build rate of 3,600 cc/hr, which makes it faster and more affordable to operate than comparably sized systems in the market today.

- X1 160Pro™ extra-large metal 3D printer, which is in production at ExOne’s German facility and shipping to customers soon. With a maximum print speed of 10,000 cc/hr, the 160Pro is ExOne’s 10th and most anticipated metal printer ever – offering the best value when considering size, speed, and material flexibility. Market demand for the 160Pro has been stronger than expected.

- InnoventPro™, which comes to market in late 2021 with a 3-liter or 5-liter build volume and is a faster version of the Innovent+® – the world’s most popular metal binder jetting system since 2016. Final specifications for the InnoventPro will be released closer to production in late 2021.

The ExOne Production Metal Cost Calculator is now live at www.exone.com/productioncalculator.

ExOne Delivers Unparalleled Material Flexibility

ExOne’s complete family of Pro series printers is qualified to 3D print more than 20 materials, including 11 single-alloy metals, five composite metals and four ceramics. Printable metals include 17-4PH, 316L, 304L, Cobalt Chrome, Copper, H13 Tool Steel, Inconel 718, Inconel 625, M2 Tool Steel, Titanium, and Tungsten Heavy Alloy.

Aluminum, which is already qualified for R&D use on ExOne systems, has been fast-tracked for ExOne’s highest third-party qualification status, which indicates general market readiness. ExOne’s first aluminum alloys are expected to receive this status upgrade during 2021.

What is Binder Jet 3D Printing?

Binder jetting is a groundbreaking 3D printing process that uses a digital file to quickly inkjet a binder into a bed of powder particles — metal, sand or ceramic — creating a solid part one layer at a time. When printing metals, the final part must be sintered in order to fuse the particles together into a solid object.

Binder jetting is a sustainable method of manufacturing that reduces material waste to less than 5%, saves energy by consolidating many assembled parts and processes into one, and can deliver end-use products that are 30-40% lighter — for more efficient cars, planes and military equipment.

About ExOne

ExOne is the pioneer and global leader in binder jet 3D printing technology. Since 1995, we’ve been on a mission to deliver powerful 3D printers that solve the toughest problems and enable world-changing innovations. Our 3D printing systems quickly transform powder materials — including metals, ceramics, composites and sand — into precision parts, metalcasting molds and cores, and innovative tooling solutions. Industrial customers use our technology to save time and money, reduce waste, improve their manufacturing flexibility, and deliver designs and products that were once impossible. As home to the world’s leading team of binder jetting experts, ExOne also provides specialized 3D printing services, including on-demand production of mission-critical parts, as well as engineering and design consulting. Learn more about ExOne at www.exone.com or on Twitter at @ExOneCo. We invite you to join with us to #MakeMetalGreen™.

View source version on businesswire.com: https://www.businesswire.com/news/home/20210112005220/en/

Contact:

Media:

Sarah Webster

Chief Marketing Officer

724-516-2336