- Aluminum is a strong, lightweight material that can help to lower the weight of products

- ExOne binder jet 3D printers can now 3D print 23 materials, including 12 single-alloy metals

- Titanium is now fast-tracked for qualification in partnership with a global medical device firm

NORTH HUNTINGDON, Pa. — (BUSINESS WIRE) — March 11, 2021 — The ExOne Company (Nasdaq: XONE), the global leader in industrial sand and metal 3D printers using binder jetting technology, today announced that aluminum alloy 6061 is now a Customer-Qualified material in collaboration with Ford Motor Co.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20210311006023/en/

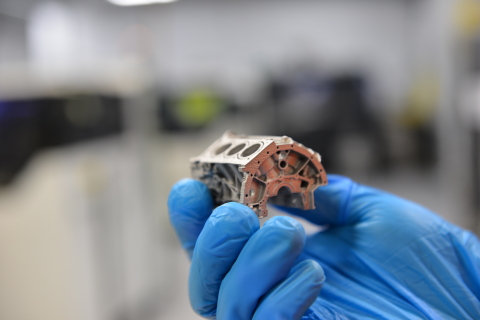

This 6061 aluminum engine block model demonstrates the high resolution and geometric control that can be produced in a new patent-pending binder jet 3D printing and sintering process developed by ExOne and Ford Motor Co. (Photo: Business Wire)

A new patent-pending process to binder jet 3D print and sinter the material delivers rapid and repeatable results: 99% density and material properties comparable to die casting. Additional collaborative and individual patents are expected to be filed by Ford and ExOne as a result of the ongoing project, as detailed in today’s simultaneous announcement.

“There has been skepticism for years that binder jet 3D printing and sintering of aluminum was even possible,” said Rick Lucas, ExOne Chief Technology Officer and VP, New Markets. “Manufacturers in other technology areas have struggled to deliver a commercially viable solution in this area for more than a decade. But at ExOne, we take pride in collaborating with our customers to solve the toughest challenges. We believe this innovation will help deliver lighter products and sustainability benefits that will have a sweeping impact across a wide range of products.”

To date, ExOne has now qualified 23 metal, ceramic and sand materials for use on its industrial binder jetting printers. With the addition of aluminum, that now includes 12 single-alloy metals. Titanium is now fast-tracked for qualification in partnership with a global medical device company.

Because ExOne technology can 3D print almost any powder, the company has a tiered material qualification system to signify the varying levels of material property results that parts 3D printed with its technology will deliver. These levels help manufacturing customers understand whether ExOne binder jetting technology could meet their specific application needs:

- Third-Party Qualified: The material has passed rigorous ExOne tests over multiple builds and has verified material property data from an independent third party. These materials meet MPIF, AMS, or other material standards.

- Customer-Qualified: These materials have been qualified by ExOne customers with their own standards and are being successfully printed today for their own applications. However, they have not yet earned ExOne’s highest level of qualification for general market readiness. ExOne routinely partners with manufacturers to develop materials for specific applications.

- R&D Materials: These materials have been deemed printable by ExOne and our customers after preliminary analysis. R&D work for these materials is ongoing and involves engineering work with the materials, as well as our printers and processes, to ensure successful printing.

Additional Information About Aluminum Binder Jetting

Shaping aluminum alloys into lightweight designs with today’s manufacturing technologies can be a challenge whether using traditional or additive 3D manufacturing technologies. Generally speaking, the higher the strength of aluminum alloy, the more challenging and expensive it is to shape into parts.

3D printing has long been viewed as a potential pathway to simplify manufacturing of the material, but engineers have struggled for more than a decade to deliver a commercially viable method of sintering the material when using binder jetting – the fastest method of 3D printing and the most desirable for high volume output. Laser-based methods of 3D printing can deliver aluminum but those processes are regarded as too slow for volume production.

Binder jetting is a 3D printing process that uses a digital file to quickly inkjet a binder into a bed of powder particles — metal, sand or ceramic — creating a solid part one layer at a time. When printing metals, the final part must be sintered in order to fuse the particles together into a solid object.

ExOne’s qualification of aluminum in collaboration with Ford is the result of a new patent-pending process for binder jet 3D printing and sintering. The achievement is highlighted even further by the fact it is being accomplished without excessive levels of liquid-phase sintering that leads to melting and distortion; this would prohibit many of the capabilities that bring manufactures to 3D printing in the first place, such as unique geometries.

About ExOne

ExOne is the pioneer and global leader in binder jet 3D printing technology. Since 1995, we’ve been on a mission to deliver powerful 3D printers that solve the toughest problems and enable world-changing innovations. Our 3D printing systems quickly transform powder materials — including metals, ceramics, composites and sand — into precision parts, metalcasting molds and cores, and innovative tooling solutions. Industrial customers use our technology to save time and money, reduce waste, improve their manufacturing flexibility, and deliver designs and products that were once impossible. As home to the world’s leading team of binder jetting experts, ExOne also provides specialized 3D printing services, including on-demand production of mission-critical parts, as well as engineering and design consulting. Learn more about ExOne at www.exone.com or on Twitter at @ExOneCo. We invite you to join with us to #MakeMetalGreen™.

View source version on businesswire.com: https://www.businesswire.com/news/home/20210311006023/en/

Contact:

Media:

Sarah Webster

724.516.2336

sarah.webster@exone.com

Doug Braunsdorf

1.646.899.7687

doug.braunsdorf@bcw-global.com