Expanded service enables dentists to more easily offer world’s thinnest cosmetic dental veneers across the United States

MAYNARD, Mass. — (BUSINESS WIRE) — November 19, 2024 — Boston Micro Fabrication (BMF), a leader in advanced manufacturing solutions for ultra-high precision applications, today opened the UltraThineer™ Lab at its U.S. headquarters in Maynard, Mass. to advance the production of UltraThineer veneers. The UltraThineer Lab will house BMF’s proprietary technology, projection micro stereolithography (PµSL), to custom manufacture cosmetic veneers that are three-times thinner than traditional veneers, enabling dentists to offer the world’s thinnest custom veneers to their patients in the U.S.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20241119951433/en/

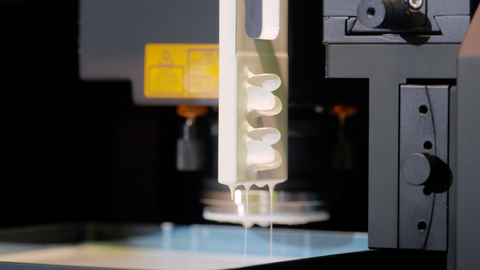

UltraThineer, the world's thinnest cosmetic veneers, printed by BMF's proprietary PµSL (projection micro stereolithography) (Photo: Business Wire)

"I believe it is important to preserve natural, healthy teeth while offering patients subtle enhancements like shade changes and shape adjustments. Traditional veneering processes often require significant tooth reduction and can cause sensitivity to the teeth,” said Jessica Birrell, owner of Capture Dental Arts. “With UltraThineer's ultra-thin, printed zirconia veneers, conservative dentistry is now redefining and simplifying the process, making conservative veneering more accessible than ever before."

Since receiving FDA 510(k) clearance for its innovative UltraThineer material in the spring of 2024, BMF has collaborated with industry-accredited dental labs to administer test cases using the veneers. At just 0.08 mm thick, the ultra-thin and strong 3D printed zirconia veneers offer patients a highly precise fit for aesthetic restoration, whereas traditional veneers are manufactured to a thickness of approximately 0.5 mm or more. Patients who elect to receive UltraThineer veneers can achieve optimal cosmetic results with significantly less preparation, allowing for preservation of the patient’s enamel with less reduction.

“Our approach to innovation has centered on applications where our ultra-high precision technology can make the biggest impact. Following FDA clearance of the UltraThineer material, the UltraThineer Lab allows us to meet the demand for thinner and less invasive veneers,” said John Kawola, CEO-Global, BMF. “While additive manufacturing is already proven across multiple dental applications, such as orthodontic aligners, UltraThineer was designed to offer a more seamless alternative to traditional veneers giving dentists and patients a more comfortable and less invasive option for cosmetic dentistry.”

BMF is now recruiting dental labs as collaborative partners as they look to bring UltraThineer veneers to dental practices across the U.S., and the company welcomes interested entities to reach out and explore potential partnership opportunities.

In tandem, BMF continues to offer cosmetic dentistry solutions in international markets to support both direct-to-patient and provider-enabled access to thinner veneers. For more on Venust, the consumer cosmetic dentistry solution available in China, please visit www.venust.cn. For more on LaBriller, available only in Japan, please visit https://nanoism.co.jp/.

For more information about UltraThineer veneers and partnership opportunities, please visit https://ultrathineer.com/lab-contact-us/

About Boston Micro Fabrication (BMF)

Boston Micro Fabrication (BMF) enables highly precise, micro-scale 3D printing across healthcare, the life sciences, electronics, and machining industries. Using the company’s proprietary PμSL (Projection Micro Stereolithography) technology, the microArch system printers produce the industry’s most accurate and precise high-resolution 3D prints for product development, research, and industrial short run production. Founded in 2016, BMF has offices in Boston, Shenzhen, Chongqing and Tokyo with a research and development center in San Diego. For more information on BMF please visit www.bmf3d.com or follow the company on LinkedIn.

View source version on businesswire.com: https://www.businesswire.com/news/home/20241119951433/en/

Contact:

Jessika Parry

BMF@greenoughagency.com